Exploring Aluminium Cutting and Its Industrial Applications

September 4, 2024

Choosing the Right Anodized Aluminium Colors for High-Performance Projects

August 22, 2025The Role of Aluminium Profiles in Automation in Malaysia: A Smarter Way to Build

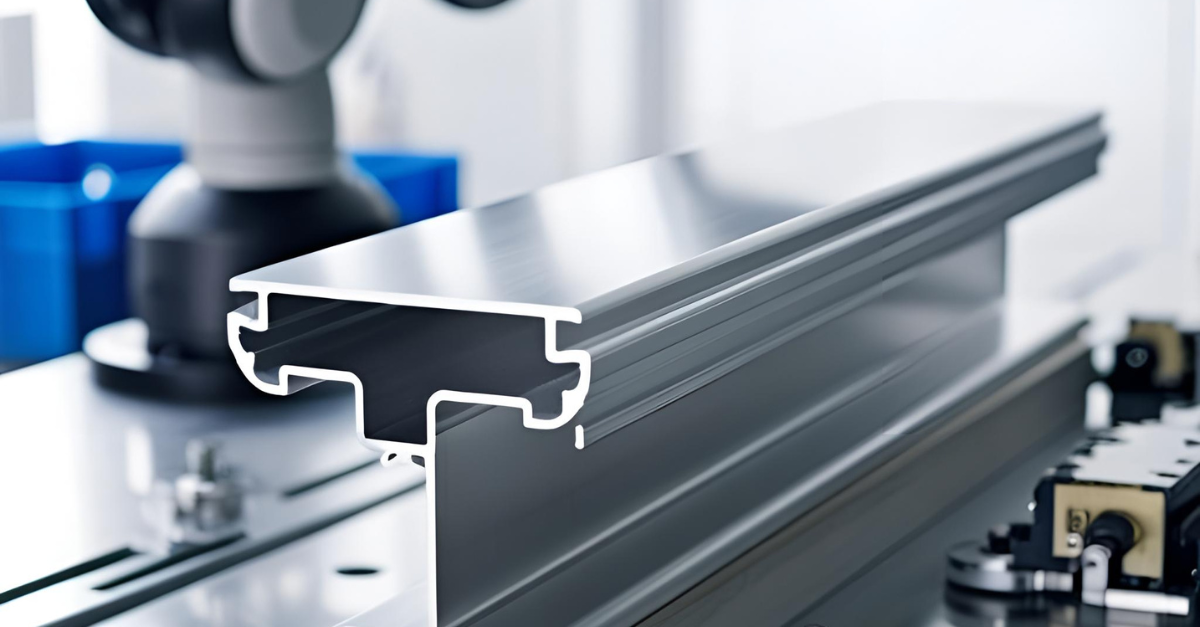

As industries rapidly adopt automation and Industry 4.0, the materials used to build machinery and production lines have become just as important as the technology itself. Among the key building blocks of modern automation systems are aluminium extrusion profiles—versatile, lightweight, and durable components that serve as the backbone for automated systems, from conveyor setups to robotic arms.

At ALUMAC, a trusted aluminium supplier in Malaysia, we’ve seen first-hand how precision-engineered industrial aluminium profiles contribute to faster installation, lower costs, and more flexible manufacturing systems.

Why Industrial Aluminium Profiles are Crucial for Automation Systems

1. Lightweight Yet Strong:

Aluminium offers a high strength-to-weight ratio, making it ideal for movable structures like robotic arms and gantry systems. It reduces the load on motors and drives, improving energy efficiency and performance.

2. Corrosion Resistance for Longevity :

Automation environments often include humidity, heat, or chemical exposure. Aluminium’s natural oxide layer provides corrosion resistance, making it perfect for long-lasting automation equipment with minimal maintenance.

3. Modularity and Flexibility:

Unlike welded steel frames, aluminium profiles are modular. This allows engineers to quickly adjust, expand, or dismantle systems as needs evolve—especially crucial in fast-changing manufacturing lines.

4. Clean and Aesthetic:

Automation systems in cleanrooms, electronics, or food industries require materials that don’t rust or flake. Aluminum’s clean finish, especially when anodized, ensures compliance with hygiene and quality standards.

Common Applications in Automation

- Machine Frames and Enclosures

- Conveyor Systems

- Workstations and Trolleys

- Robotic Arm Structures

- Safety Fences and Guards

With over 30 years of experience in aluminium extrusion in Malaysia, ALUMAC has supported OEMs, integrators, and manufacturers across the electrical & electronics, packaging, and industrial automation sectors. Whether you’re designing a new assembly line or upgrading existing systems, our high-quality aluminium profiles in Malaysia help bring efficiency and flexibility to your automation projects.

References

- European Aluminium Association. (2023). Aluminium in Transport and Automation. Retrieved from: https://european-aluminium.eu

- Bosch Rexroth. (2022). Modular Aluminum Framing for Automation. Retrieved from: https://www.boschrexroth.com

- International Aluminium Institute. (2024). Industrial Uses of Aluminium. Retrieved from: https://international-aluminium.org

- Markets and Markets. (2023). Industrial Automation Market by Component and Material Type.