An aluminium alloy is a chemical composition where other elements are added to pure aluminium in order to enhance its properties, primarily to increase its strength. These other elements include iron, silicon, copper, magnesium, manganese and zinc. Alloys are assigned a four-digit number, in which the first digit identifies a general class, or series, characterized by its main alloying elements. All this while, ALUMAC only getting the aluminium alloy billet from TWO reliable sources to ensure the consistency of material in term of hardness, dimension & surface appearance. We have ensured that all the alloy billet we use passed in the Spark Metal Composition Test.

- Extruded Product Alloys

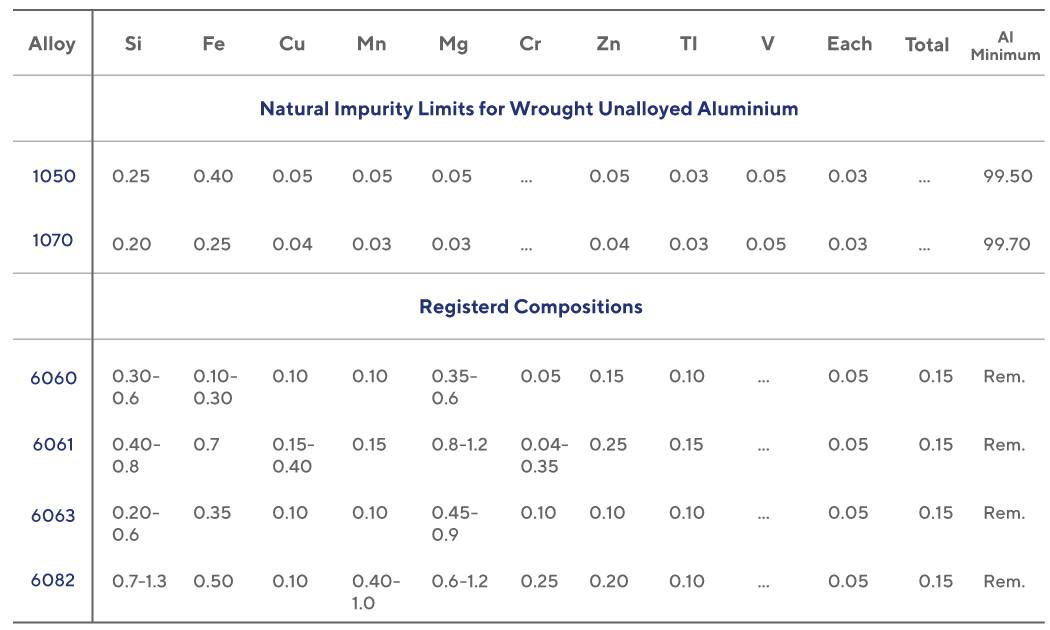

- Chemical Composition Limits

- Mechanical Properties Limit - Extruded Wire, Rod and Bar

Description

1050 is a high purity non-heat treatable alloy with 99.5% aluminium content. These compositions are characterised by excellent corrosion resistance, high thermal and electrical conductivity, low mechanical properties and excellent workability. Iron and silicon are the major impurities.

Application

Use in electrical and chemical fields which require the highest available electrical conductivity performance

Description

1070 is a high purity non-heat treatable alloy with 99.70% aluminium content. These compositions are characterised by excellent corrosion resistance, high thermal and electrical conductivity, low mechanical properties and excellent workability. Iron and silicon are the major impurities.

Application

Use in electrical and chemical fields which require the highest available electrical conductivity performance

Description

6060 is one of the most common alloys of 6000 series. It is a heat treatable alloy with very good corrosion resistance and weldability. It is an ideal alloy for every complex cross section and has a very good anodizing response.

It cannot be work hardened but is commonly heat treated to produce temper with a higher strength but lower ductility

Application

- Architectural applications including doors and windows frames

- Electrical components and conduits

- Tube for irrigation systems

- Curtain walls

- Lightning, furniture and picture frames

- Carpet edging

- Railings and fences

- Applications where surface finish is important

Description

6061 is a heat treatable alloy with mechanical properties slightly lower than 6082. It has good corrosion resistance but the extruded surface finish is not as good as 6060.

Application

- Road and rail transport

- Marine

- Scaffold tube

- Structural members

- Cycling frames and components

- Breathing gas cylinders for scuba diving and SCBA

Description

6063 is a heat treatable and weldable. It is commonly used for aluminium extrusion. It allows complex shapes to be formed with very smooth surface fit for anodizing. Application required higher strength typically use 6061 and 6082 instead.

Application

- Architectural applications including doors frame, windows frame, roof, and sign frames

- Cycling frames and components

Description

6082 has excellent corrosion resistance and the highest strength of the 6000 series structural alloys. The extruded surface finish is not as good as alloys such as 6060 and 6063.

6082 has good weldability and is commonly used in marine applications

Application

- Highly stressed applications

- Bridges

- Cranes

- Marine applications

- Other transport applications

Source : The Aluminum Association ( International Alloy Designations and Chemical Composition Limits for Wrought Aluminium and Wrought Aluminium Alloys, Jan 2015)

Source : The Aluminum Association (International Alloy Designations and Chemical Composition Limits for Wrought Aluminium and Wrought Aluminium Alloys, Jan 2015)